Metal Roof Tile Sheet Roll Forming Machine Roofing Tiles Houses Building Materials

Overview Product Description Metal Roof Tile Sheet Roll Forming Machine Roofing Tiles Houses Building Materials 01 PLC B

Overview

PLC

Brand

PLC brand:Delta

Inverter brand:Delta Low electric

part:Schneide

Encoder:OmronFunction:

1.Adoptedaviation plugseasy

installation.

2.Full automatic easy operation.

3.0peration language:English(providecustomized

4.National coinsurancespar parts Brand Siemensand

Schneide.02

TRANSMISSION DEVICE

Gearbox drive stable and no loose.03

ROLL FORMING DEVICE

1.45# SteelChromed Treatment (Cr Thick ness:0.05 Mm),Anti-Corrosion,Increase Hard- ness, Ensure The Precision And Good Abra-

sion Performance.

2. Each roller has number and with keynotes,

it can fix on the shaft stablely

04

FEEDING DEVICE

1. Rubber rollers protect raw material surface

2. With handwheels easy adjust for feeding differ- ent thickness raw material.

3.the platform width is adjustable by hand wheel, have the bearing inside to protect the edge of the steel sheet.

05

HYDRAULIC CUTTING DEVICE

1.Adopt double oil cylinder more stable than single oil cylinder

2.Hydraulic motor power 5.5 kw with energy accumulator

3.Cutter material:GB-Cr12 with heat treatment

4.Cutting length tolerance±10m/2mm

5.Cutting feature:Steady and safe working condition and low

sounds

2. Do you sell only standard machines?

A: No, most of our machines are built according to customers specifications, using top brand name components.

3.How many workers to operate the machine?

A:Only 1-2 workers.

4. How to visit your company?

a.Fly to Beijing airport: By high speed train From Beijing Nan Station to Cangzhou West Station(1 hour), then we can pick you up .b.Fly to Shanghai Airport: By high speed train From Shanghai Hongqiao to Cangzhou West station(4.5 hours), then we can pick you up.

5. What can you do if the machine broken?

Our machine's warranty period is 12months,if the broken parts can't be repaired,we can send the new parts to replace the broken parts for free,but you need pay the express cost yourself.if over warranty period,we can for to solve the problems via negotiation,and we supply the technical support for the whole life of the equipment.

6.How can I trust you that machines pasted testing running before shipping?

A: 1) We record the testing video for your reference. Or,2) Please visit company and test machine if convenient.

Basic Info.

| Model NO. | Steel Tile Making Machine |

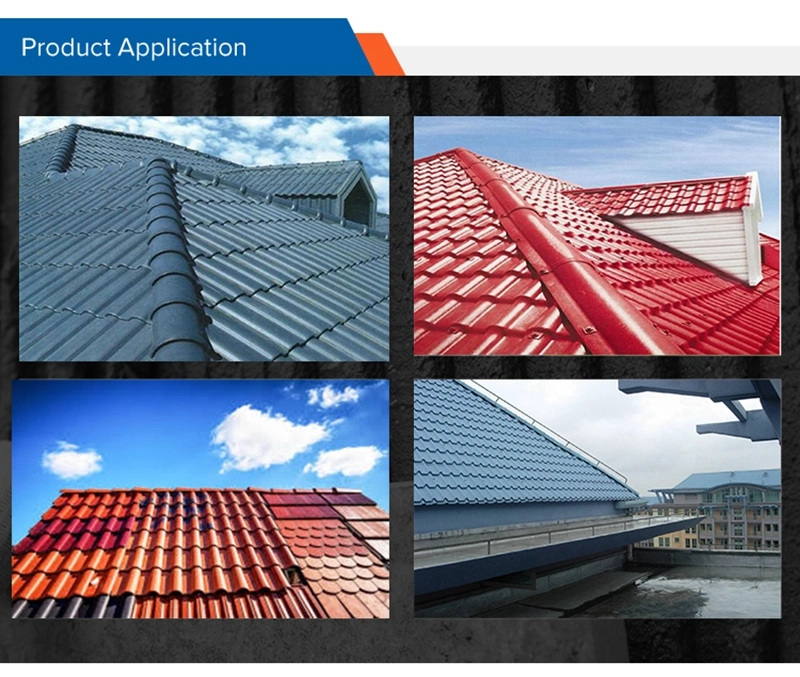

| Usage | Roof, Wall, Floor |

| Transmission Method | Electric |

| Controller | PLC, Auto Count Length and Quantity |

| Main Base | H Steel Weld |

| Roller | Cr12, Chromed, Prevent Abrasionanti Corrosion |

| Rolling Shaft | 40cr, Tempering to Improve Hardness |

| Transport Package | Standard Export Package |

| Trademark | KEFA |

| Origin | Cangzhou |

| HS Code | 845522 |

| Production Capacity | 100/Pic/Year |

Product Description

Product Description

Metal Roof Tile Sheet Roll Forming Machine Roofing Tiles Houses Building Materials

01PLC

Brand

PLC brand:Delta

Inverter brand:Delta Low electric

part:Schneide

Encoder:OmronFunction:

1.Adoptedaviation plugseasy

installation.

2.Full automatic easy operation.

3.0peration language:English(providecustomized

4.National coinsurancespar parts Brand Siemensand

Schneide.02

TRANSMISSION DEVICE

Gearbox drive stable and no loose.03

ROLL FORMING DEVICE

1.45# SteelChromed Treatment (Cr Thick ness:0.05 Mm),Anti-Corrosion,Increase Hard- ness, Ensure The Precision And Good Abra-

sion Performance.

2. Each roller has number and with keynotes,

it can fix on the shaft stablely

04

FEEDING DEVICE

1. Rubber rollers protect raw material surface

2. With handwheels easy adjust for feeding differ- ent thickness raw material.

3.the platform width is adjustable by hand wheel, have the bearing inside to protect the edge of the steel sheet.

05

HYDRAULIC CUTTING DEVICE

1.Adopt double oil cylinder more stable than single oil cylinder

2.Hydraulic motor power 5.5 kw with energy accumulator

3.Cutter material:GB-Cr12 with heat treatment

4.Cutting length tolerance±10m/2mm

5.Cutting feature:Steady and safe working condition and low

sounds

Product Parameters

| ltem | Name | Description |

| 1 | Decoiler | Capacity:5 tons |

| 2 | Material | Steel Coil |

| 3 | Thickness | 0.3-0.8mm |

| 4 | Transmission | chain/Gear/Gearbox |

| 5 | Speed | 15m/min |

| 6 | Roller | 40Cr steel with quenched treatment,chromedd on the surface |

| 7 | Shaft | steel with tempering treatment |

| 8 | Cutting type | Hydraulic cutting |

| 9 | Cutting material | Cr12 with quenched treatment Hardness58-62 |

| 10 | Welding | Automatic spot welding |

| 11 | Control system | PLC |

| 12 | Electric brand | Delta,Siemens, Schneide |

| 13 | Voltage | 380V,50HZ,3PH(or as customers'requesr) |

Detailed Photos

Company Profile

Certifications

Packaging & Shipping

FAQ

1.How to maintain the machine?

Answer: add mechanical lubrication equipment to chain, bearing and cutting slide every month. Add mechanical lubrication to the case every half a year.2. Do you sell only standard machines?

A: No, most of our machines are built according to customers specifications, using top brand name components.

3.How many workers to operate the machine?

A:Only 1-2 workers.

4. How to visit your company?

a.Fly to Beijing airport: By high speed train From Beijing Nan Station to Cangzhou West Station(1 hour), then we can pick you up .b.Fly to Shanghai Airport: By high speed train From Shanghai Hongqiao to Cangzhou West station(4.5 hours), then we can pick you up.

5. What can you do if the machine broken?

Our machine's warranty period is 12months,if the broken parts can't be repaired,we can send the new parts to replace the broken parts for free,but you need pay the express cost yourself.if over warranty period,we can for to solve the problems via negotiation,and we supply the technical support for the whole life of the equipment.

6.How can I trust you that machines pasted testing running before shipping?

A: 1) We record the testing video for your reference. Or,2) Please visit company and test machine if convenient.

Send to us