Prefabricated Concrete Hollow Core Slab Machine

1 Why eps wall panel is more and more popular? 1 -lightweight :The lighter material of the wall panel used weighs 25% to

Basic Info.

| Model NO. | concrete wall board making machine |

| Screw Design | Double-Screw |

| Certification | CE, ISO |

| Condition | New |

| Customized | Customized |

| Application | Construction Material Machine |

| Factory Workers | More Than 500 Hundred |

| Factory Area | 60, 000 Sqm |

| Factory Brand | Oyade |

| Factory History | 16 Years in Producing Wall Panel Machine |

| Production Time | 30-45 Days |

| Payment Term | T/T |

| After Sales Service | Engineer Go to Sellers Factory to Install |

| Min Production Capacity | 30, 000 Sqm Per Year |

| Wall Pane Raw Material | Cement Sandwich Water EPS |

| Wall Panel Application | Internal and External Walls |

| Factory Site | Jinan City Shandong Province |

| Main Market | Middle East African, South American |

| Hollow Core Wall Panel Width | 600mm |

| Hollow Core Wall Panel Thickness | 75-300mm |

| Hollow Core Wall Panel Length | 3000-3600mm |

| Transport Package | Export Standard Package in 40FT Container |

| Specification | based on production capacity |

| Trademark | OYADE |

| Origin | China |

| HS Code | 8474802000 |

| Production Capacity | 500 Sets Per Year |

Product Description

1 Why eps wall panel is more and more popular?1 -lightweight :The lighter material of the wall panel used weighs 25% to 40% of the weight of the bricks

2 -High thermal insulation

3 - Remove a higher sound

4 -Install faster 4 Times than the regular blocks

5 - Wall does not need the expenses of the work of the plaster

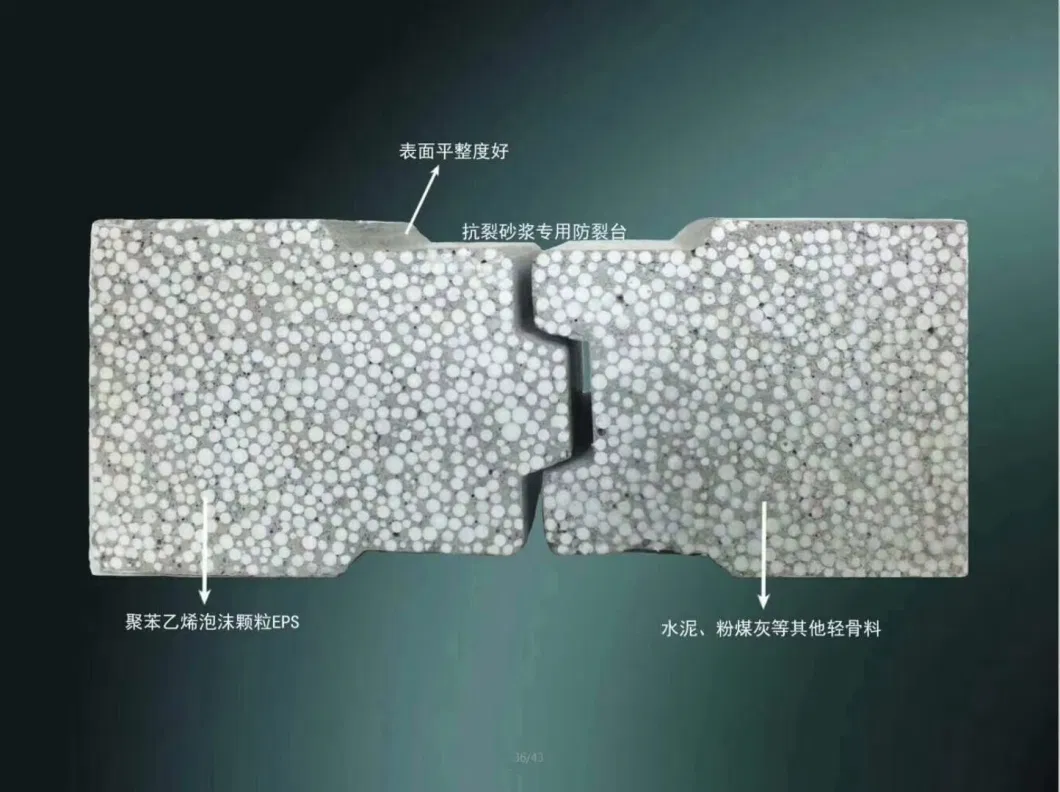

2 raw material of eps lightweight sandwich and soild wall panel

| Raw material detailed introduction | |

| Cement | It it the basic raw material for wall panel. |

| Fly ash | 1) reduce the amount of cement 2) increase the area density of the wall panels 3) increase the fluidity of the slurry 4) It can be replaced to cement |

| EPS particle | It makes wall panel lighter, higher performance in thermal insulation. |

| Surface board | Calcium silicate board or fiber cement board. You can check which kind is available in your market. |

| Sand | Add some sand (diameter ≤3mm) improve strength of wall panel. |

| Chemical additives | It makes cement foaming, which reduce cement usage quantity |

| Note: 1Others construction rubbish, rice husk, perlite, ties, flyash and so on 2Using normal cement, no steam curing facilities, the temperature is about 20 °C So for the wall panel's raw material, it is very widely. So this project is higher feasibility in every country. | |

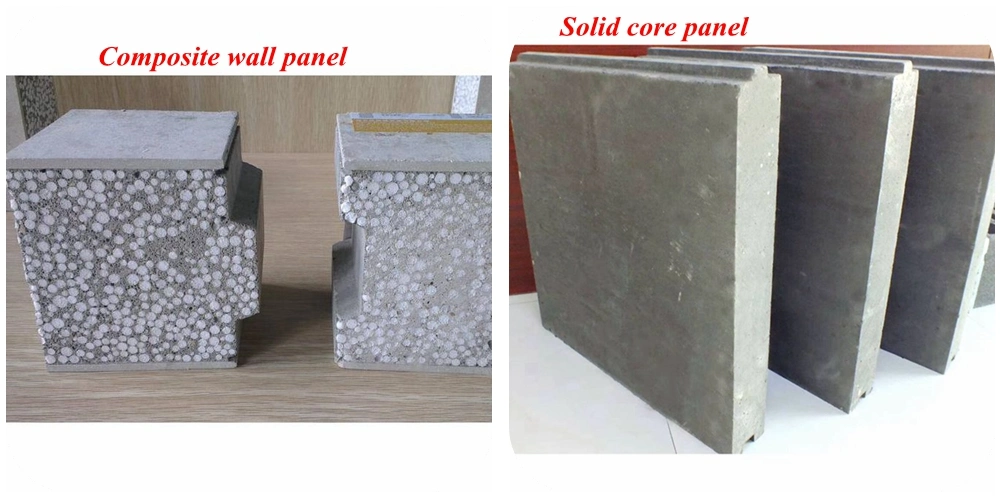

3 Two functional vertical mold car

We have double function mould car , it not only can produce sandwich wall panel ,also can produce solid panel to meet different market demand . moreover,our solid panel technology is No.1 in China.

4 The specification of wall panel :

| Machinery Parameters | |

| Configuration: | Automatic metering system |

| Capacity | 20,000sqm~600,000sqm per year |

| Thickness | 50-250mm thickness. |

| Length | 2440~3600mm, |

| Width | 610mm , |

| Raw materia | There are mainly two different types |

| 1. Cement+fly ash/eps/ceramsite/sand | |

| 2. Foamed cement+additives | |

| Finished board type | 1. Composite board/sandwich board, with surface board |

| 2. Lightweight solid panel, without furface board | |

| Surface board types | 1. Calcium silicate board |

| 2. Fiber cement board | |

| 3. Mgo board | |

5 Our factory -Shandong Oyade Group

OYD group was established in 2008. she has 5 subsidiaries for producing different kinds of products, eps concrete wall panel production line; mgo board /fiber cement board production line; hollow glass aluminum spacer; Laser cutting machine , etc. OYD Philosophy : O and Y means the global market, with the top quality machine to occupy more market. D, is related with a Chinese idiom, means the person who has the high prestige and trustworthy. So the OYD means that Be a sincere person first, Occupy the market share through top quality products.

6 Our proejct in South Ameican

We are specialized in designing and manufacturing lightweight wall panel production line. With rich experience in mechanical design and manufacturing, professional import and export services, we commitment to provide the best integrated solutions of production line for customers.Our general engineer has over 20 years' experience in mechanical industry, proficient in the newest machinery design/manufacturing. Other main engineers all have over 10 years' experience. After installation and commissioning, we will provide technical formula suitable with client's demand, ensuring clients can produce qualified finished products. Additionally, we will help local experienced engineers to master the production process.Our professional sales team, designing team, manufacturing team, installation team, process team, service team, promises you a 100% perfect project.

project in QATAR

Loading containers for customer

Widly application of eps lightweight wall panel with steam frame

FAQ

| 1. | How to curing the wall panel ? |

| Normally curing time is 8-12hours , it can adjust according to your local temperature , also need natural curing around 25-28days before use it . | |

| 2. | Q: How long is the warranty of your equipment? |

| A: 1year ,but we will provide after-sale service the whole life cycle | |

| 3. | Q: Do you supply spare parts? |

| A: Excellent easy broken parts support for buyers. Easy broken parts guarantee for one year.Other parts we will provide price list in advance . | |

| 4. | Q: Will you provide trainning and formula? |

| A: The training is free of charge , and our engineer will be on duty to train your worker until they know how to produce qualifyed product .Also we will provide you qualified formula | |

| 5. | Q: How will you provide installation&commissioning |

| A: Will provide 1-2 persons(adjustable according to the degree of automatic )for installation.Engineers team will go with your project. , besides we only need 15days for commission .in this way can help you save cost on raw material and time . |

Contact Us

Sherry

Send to us