PP Polypropylene Plastic Twin Wall Hollow Grid Fluted Colorful Corrugated Correx Sheet Board Panel Making Machine for Vegetable Fruit Carton Packing Box

Basic Info.

| Model NO. | SJ-120/36 |

| Plastic Processed | PP |

| Product Type | Sheet Extruder |

| Feeding Mode | One Feed |

| Assembly Structure | Separate Type Extruder |

| Screw | Single-Screw |

| Engagement System | Full Intermeshing |

| Screw Channel Structure | Deep Screw |

| Exhaust | Exhaust |

| Automation | Automatic |

| Computerized | Computerized |

| Motor Brand | Siemens |

| Line-Speed | 2-6m/Min |

| Machine Color | Customized |

| Main Electric Component | ABB, Omron, Siemens etc |

| Sheet Thickness | 1.8-12mm |

| Output Capacity | 250-350kg/H |

| Sheet Width | 1000-2800mm |

| Transport Package | as Export Standard |

| Specification | 20T |

| Trademark | QINGDAO TONGSAN |

| Origin | Qingdao, China |

| HS Code | 84772090 |

| Production Capacity | 30 Sets One Year |

Packaging & Delivery

Package Size 2500.00cm * 200.00cm * 200.00cm Package Gross Weight 15000.000kgProduct Description

PP hollow sheet extrusion line

This production line realizes continuous production of PC/PE/PP hollow grid plate, which is applicable to construction decoration, advertisement collocation, and noise insulation of highway as well as packaging. PE/PP hollow grid plate is an ideal substitute for paper box in making packaging box. It is characterized by light weight, high intensity, dampproof, and anticorrosion. The width of the products is 1220-2100mm, and the thickness is 2mm-12mm.Plastic PP hollow board is mainly used in electronics, packaging, machinery, light industry, postal services, food, medicine, pesticides, household appliances, advertising, decoration, stationery, magneto-optical technology, bio-engineering and other medical and health industries. It is a new type of environmentally friendly packaging materials.

| Model | Sheet width | Sheet thickness | Extruder model | Motor powder |

| TS-1400 | 1250mm | 2-6,8-12mm | 100/36 | 55-75kw |

| TS-1860 | 1700mm | 2-6,8-12mm | 120/36 | 75-90kw |

| TS-2300 | 2150mm | 2-6,8-12mm | 120/36 | 90-110kw |

| TS-2600 | 2450mm | 2-6,8-12mm | 120/36 | 90-110kw |

| TS-3000 | 2800mm | 2-6,8-12mm | 150/36 | 132kw |

| TS-2600(F) | 2450mm | 2-6,8-12mm | 120/36&80/36 | 110+37kw |

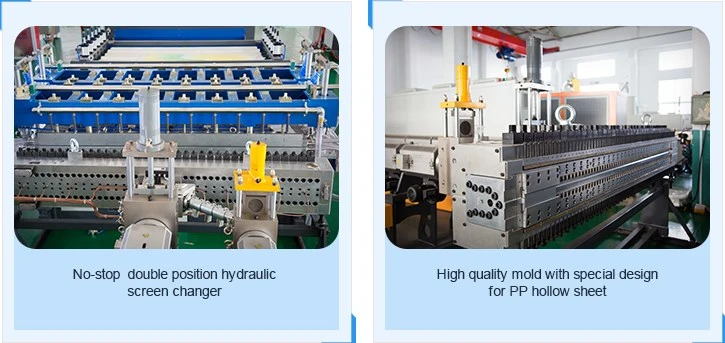

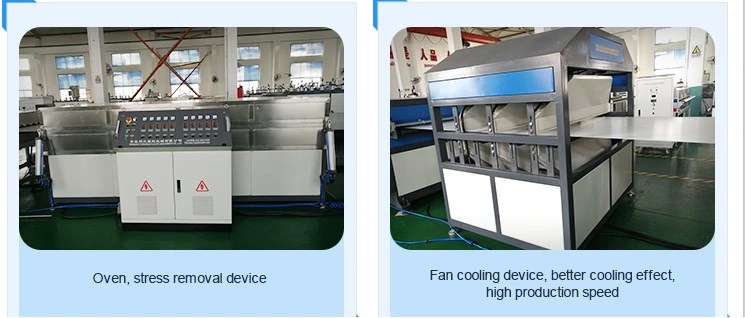

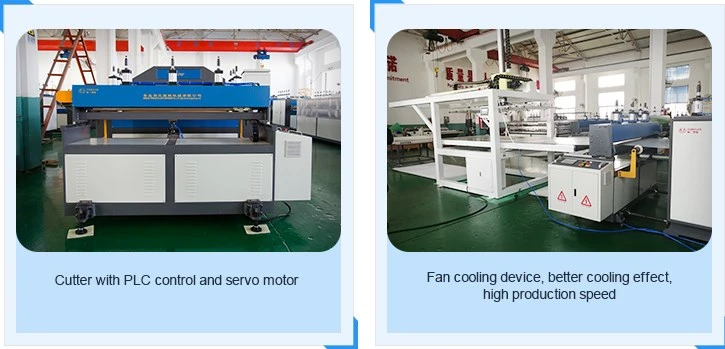

Detailed Photos

Advantages

1. Good mechanical properties

The special structure of the plastic hollow board makes it have excellent mechanical properties such as good toughness, impact resistance, high compressive strength, cushioning and shockproof, high stiffness, and good bending performance.2. Lightweight and economical materialThe plastic hollow board has excellent mechanical properties, and the same effect should be achieved year-on-year. The use of plastic hollow board has less consumables, low cost and light weight.3. Heat insulation and sound insulationDue to the hollow structure of the plastic hollow board, its heat and sound transmission effect is significantly lower than that of the solid board, and it has good heat insulation and sound insulation effects.4. Anti-static, conductive, flame retardantModification, mixing, surface spraying and other methods can make the plastic hollow board have anti-static, conductive, or flame-retardant properties.5. Stable chemical performancePlastic hollow board can be waterproof, moisture-proof, anti-corrosion, insect-proof, and fumigation-free. Compared with cardboard and wood board, it has obvious advantages.6. The surface is smooth and beautiful, with complete colorsDue to the special molding process of the plastic hollow board, any color can be achieved through the toning of the masterbatch, and the surface is smooth and easy to print.7. Obvious environmental protection effectThe plastic hollow board has the characteristics of non-toxic, non-polluting, etc., is simple to dispose of, and will not pollute the environment. It can also be reused to make other plastic products.

Application

Turnkey project of PP holllow corrugated box

Main products of our company

Company Profile

F&Q

1. Why choose usWe are the first manufacturer in Qingdao to develop plastic extruders. We have 22 years of experience in mechanical manufacturing. What we pursue is machine quality and customer satisfaction.We only choose qualified supplier -- Tongsan excellent partnerWe work closely with world famous brand,your equipment can also be equipped with any famous brand as you wish,such as Siemens motor,ABB inventer,Omron temperature controller, famous brand electric devices,etc.2. What service do we provide?Perfect service system:1.We will provide the Feasibility Analysis Report for your project.2.We will provide the model selection and technical parameter of our machinery.3.We will provide the design for the plant and electric power accounting for the facilities.4.We will provide the design for plastic formula according to the products requirement.5.We will provide the technology of plastic product surface treatment if need.6.We will provide technique training for your operator.7.We will provide solution for the production problem .8.We will install and test the machine in customer's factory.9.We will provide turnkey project to customers. 3. Payment terms30% of the total amount should be paid by wire transfer as a down payment, and the balance (70% of the total amount) should be paid (at sight) before the delivery of the wire transfer or irrevocable letter of credit4. Delivery terms:4.1 Delivery terms: FOB Qingdao Port.4.2 Delivery deadline: within 30-60 working days after receiving the advance payment, the seller shall notify the buyer to inspect. The seller should complete the packaging of the goods within 15 working days after receiving the full payment and be ready for shipment.4.3 Supervised loading: The seller should inform the buyer of the exact loading time, and the buyer should arrange the scope of supervised loading.5. Warranty terms:5.1 Warranty period: 12 months from the first day of operation of the machine in the customer's warehouse5.2 The seller shall guarantee that the service and spare parts are free of charge during the entire equipment warranty period.5.3 LIFELONG service: After the 12-month warranty, the seller shall provide LIFELONG service for the sold goods, and the buyer shall pay for the required spare parts.6. Inspection :After the machine is completed, the seller should notify the buyer to inspect before delivery, and the seller guarantees that all the goods sold are of good quality. The seller does not bear the material cost of the machine inspection in the seller's factory. The buyer should come to the seller's factory for inspection, or the buyer can invite any third party to enter the seller's factory for inspection.7. Installation and equipment debugging:If the buyer needs it, the seller should send a team of technicians to the buyer's factory for full-line operation of installation and testing, and the buyer should lift the price of the entire food/location and group purchase information (aircraft, food, hotel, etc.), and charge the engineer 150 USD/day/engineer's cost.